Frank Vickery's Bio

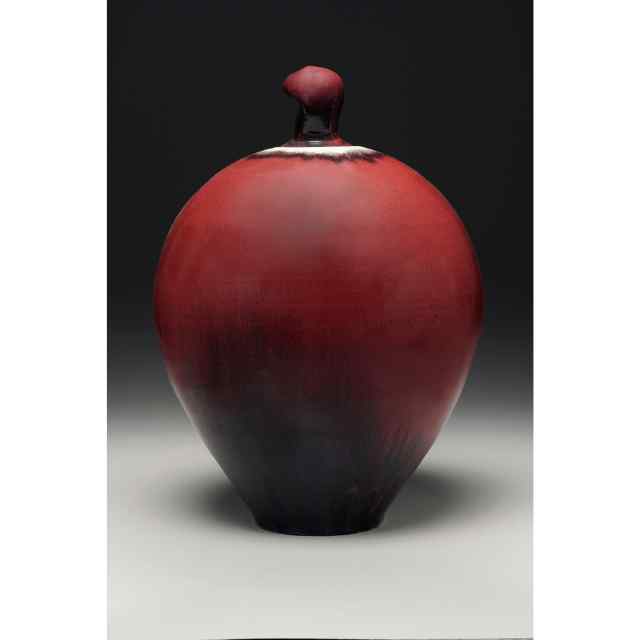

Frank Vickery has been working in clay for 20 years with multiple years devoted to instruction in clay arts. His ceramic works and teaching approach centers around the contributing education model of workshops, academia, and dedicated studio hours. Frank started his career as a middle school art teacher in Rock Hill, South Carolina. His graduate work was completed at Western Carolina University, where he earned a Master of Fine Arts degree in 2012. Frank is currently the Director of Ceramics at The Bascom where he also teaches ceramics classes. Frank is known for the quality of his work, his dedication to the field of ceramics, and his enthusiastic ability to share his talent and knowledge with his students.

Artist Statement

“Working with clay is not a supplemental part of my life, it is an essential component of my existence. As a child, barefoot in the mud, I molded mud castles from my imagination and covered myself in costumes of muck; that is how it began, a love for the plentiful material beneath my feet. Through study, process, and practice, my understanding of the possibilities of clay as a material for creation has grown far beyond the mud puddles of my youth. A part of me and the journey it took to get here, exists in every piece.” - Frank Vickery

About Crystalline Glazing

Crystalline glazing is time consuming & expensive to produce. There can be many failures, but when all goes well the effects are stunning. Crystalline glaze is mixed using a variety of ingredients, some measured in minute amounts. It is applied very thick, up to 4mm, to encourage the glaze to run. The pot is placed on a pedestal and stands in a dish to catch the runoff during the firing. When the kiln reaches the maximum temperature of 2365 ºF, it is then rapidly cooled to a specific holding temperature. The temperature is then raised and lowered, held at certain lengths to create the different bands and sizes of the crystal structure. This is the time when the crystals form in the glaze, which occur randomly, making each pot unique. When all has cooled down, there is the delicate operation of removing the pot from the pedestal and grinding the bottom smooth. The pedestal is removed by tapping the dish. This breaks the seal and the vase comes away. Removal has to be done very carefully, as this part of the process could damage the base of the pot. Once the vase has been removed from the pedestal, the edges are very sharp. A green wheel disc on a bench grinder is used to grind the base of the piece smooth.